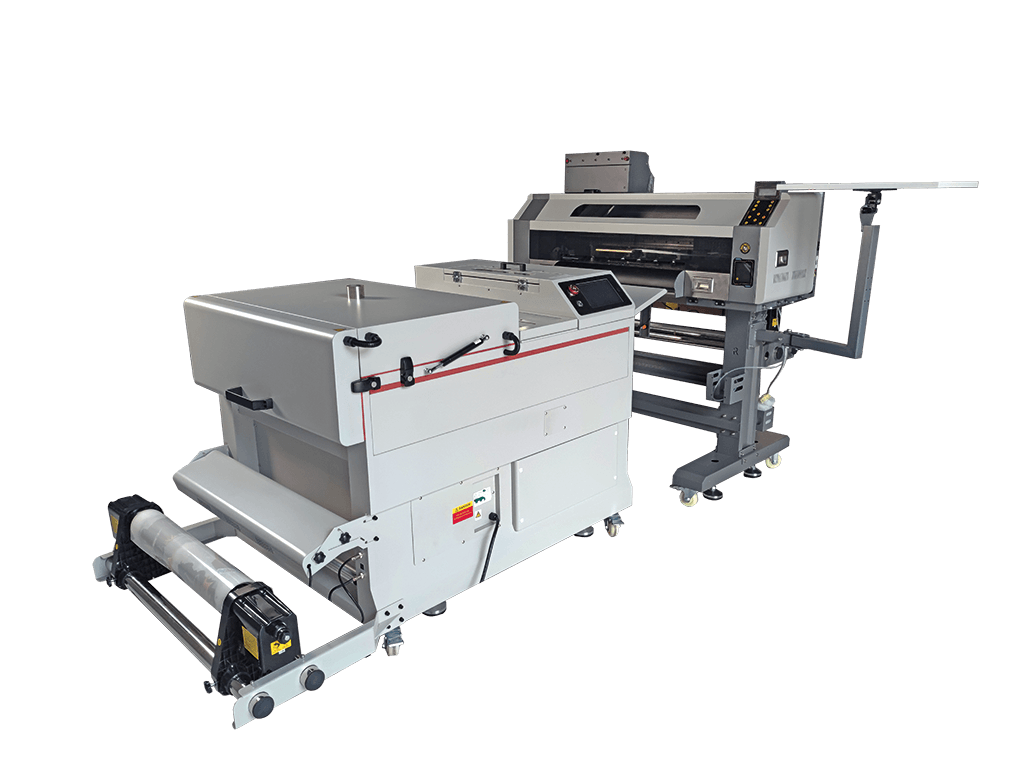

ArtisJet U3000Pro + Freebird: Power Meets Precision

Revolutionize Your Direct-to-Substrate Printing Experience

Welcome to the future of on-demand customization. The ArtisJet U3000Pro, now integrated with Freebird, delivers an unbeatable combination of industrial-grade performance and effortless automation. Whether you’re customizing drinkware, gadgets, or promotional products, the U3000Pro ensures vibrant, precise prints—every time.

DTF Printing: Unleash Your Creativity

with Personalized, Vibrant Designs

Elevate Your Designs with DTF Printing

Are you looking for a printing method that combines personalization, vibrant colors, and endless possibilities? Look no further than DTF printing. This innovative technology offers a versatile and high-quality solution for your design needs.

- Customization: Create one-of-a-kind designs tailored to your specific preferences.

- Vibrant Colors: Experience stunning color reproduction and exceptional detail.

- Versatility: DTF printing is compatible with a wide range of materials, from fabrics to hard surfaces.

- Durability: Enjoy long-lasting prints that resist fading and cracking.

Applications of DTF Printing:

- Apparel: T-shirts, hoodies, hats, and more.

- Home Decor: Pillows, blankets, wall art, and accessories.

- Promotional Items: Mugs, tote bags, and custom gifts.

WHY CHOOSE US

Why Choose Nanodiy Premium DTF Printers?

State-of-the-Art Equipment

We utilize the latest DTF printing technology to deliver exceptional results.

Experienced Team

Our skilled professionals are dedicated to providing top-notch customer service.

Competitive Pricing

Enjoy affordable rates without compromising on quality.

Years Of Experience

ABOUT US

A clear vision and strategic goals

The basic concept of our business is to provide our customers with EVERYTHING IN ONE PLACE. Our activity is the development (and sale) of technologies and ancillary equipment for the production of premium DTF printers and transfer machines.

- Our Commitment

- Unrivaled Product Range

- Quality and Reliability

- Expert Support

DTF Printers

UV DTF Printers

UV FlatBed printers

RIP Software

Mastering the Art of DTF printing

At Nanodiy, we boast years of invaluable experience in the heat transfer industry. As pioneers in the field, we take pride in offering unmatched expertise that translates into top-quality products and services. When you choose us, you’re selecting a partner with a proven track record of delivering exceptional heat transfer solutions tailored to your specific needs. Trust in our years of know-how, and let us elevate your printing projects to new heights.

Quality

Our Commitment to Excellence

Support

Your Success is Our Priority

Knowledge

Empowering Your Journey

R&D

Innovate to Elevate

Our Commitment

At Nanodiy, we are committed to excellence in everything we do. Our mission is to provide top-of-the-line heat transfer printing solutions that not only meet but exceed our customers’ expectations. We understand that each printing project is unique, and our dedicated team is here to offer personalized advice and support to ensure your success.

Unrivaled Product Range

Explore our extensive range of cutting-edge heat transfer printers and accessories, carefully curated to cater to various printing needs. Whether you’re a small business, a DIY enthusiast, or an established printing company, we have the perfect solution to fit your requirements and budget.

Ready to take your printing game to the next level?

Reach out to us today, and let's embark on a journey of creativity, innovation, and success together!

Contact us